Top Benefits of 3D printing

Understood today as 3D printing or additive manufacturing, these technologies exist in a fast-changing environment, where new processes, equipment, and applications are being established as each day passes. 3D printing will not totally change conventional production methods, it has proven its strengths and is currently reinventing lots of industrial sectors.

In this short article, we'll discuss the top 10 benefits of 3D printing in 2020 and give some real-life examples of how these marvelous technologies are being used every day.

Ease of access

Prior to diving into the more unique benefits of these technologies, let's look at a wider element of 3D printing that's arguably the most substantial of all: availability. This is a pertinent consider a couple of the advantages in our list, so we'll begin with some context.

3D printing innovations were very first established in the 1980s, not a lot occurred over the subsequent 20 years, as high expenses and stringent patent constraints restricted their usage to mostly high-end industrial applications. During this time, these baby 3D printing innovations progressed at a rather sluggish rate.

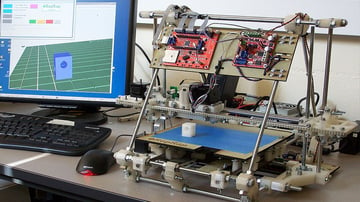

That began to change with the RepRap project in 2005, founded by a number of academics in the UK. The idea was to establish inexpensive 3D printers with open-source styles so that anyone could construct one. This was a substantial step towards ease of access and ultimately triggered a new age in 3D printing.

Open-source development and greater availability provided the push required not just to popularize the technology but also to promote further advancement in the area. Fast-forward to today and there are countless 3D printer makers and business, and essentially anybody can 3D print an item, whether in the house or through shops and online services.

With all of that said, it becomes clear that accessibility has been a core part of the growth of 3D printing, as well as among its primary advantages overall. In fact, the first 3 benefits on our list are all related to access. Let's jump in!

All in all, it was accessible equipment that significantly put 3D printing on the world map. How many 3D printing business, material suppliers, and spare-parts makers were born out of the popularization of desktop 3D printing?

Today, there's a 3D printer for everyone: different sizes, prices, innovations, you name it. Moreover, there are hundreds of comprehensive open-source styles online that, allied with numerous suppliers worldwide, allow anybody to plan and build a 3D printer from scratch at a very inexpensive.

Whether purchased or built, desktop 3D printers are fairly easy to use, which further improves ease of access. The workflow needed to process and print an item is fairly simple when compared to other digital fabrication strategies such as CNC routing or milling.

There's the other side of accessibility: the cost. Back in the early 90s, an SLA 3D printer utilized to cost around $300,000 (around $600,000 in today's figures). Twenty years later, in 2010, the typical expense of a 3D printer ranged around $50,000, which was still far too costly for many home users.

These days, depending upon your usage case, desktop resin printers range between a couple hundred and a couple of thousand dollars. At the economical end of the scale, DLP machines like the Elegoo Mars and the Anycubic Photon cost around $200 each, while two of the most popular FDM printers, the Original Prusa i3 and the Creality Ender 3, presently cost around $750 and $200, respectively.

The substantial variety of desktop printers intended for at-home usage and the large drop in price in recent years simply goes to demonstrate how available 3D printing has become.

Accessible Production

We're well past the age of corporations and big factories holding all the manufacturing resources. Owning a production device allows people to produce their own goods anywhere. This is true of many digital fabrication equipment, however especially 3D printers as they are usually little and simple to setup.

Add that to the ever-growing demand for digital modeling and you can see the entire production process shifting towards the people. This triggered the creation of lots of little production companies that were previously only possible with artisanry skills and high financial investments in physical space and devices.

This democratization of production has empowered the user, with many hobbyist-level makers now fixing and creating their own things instead of merely changing and purchasing brand-new. While lots of industrialists feel threatened by this, some have actually chosen to sign up with the motion.

One example is camera equipment company Edelkrone, which has a line of items known as Ortak made by both the company and the client. Edelkrone produces and ships the vital parts such as metal joints and electronic parts while providing the consumer digital models for 3D printing the staying parts of the item. Not only does this decrease rates, but the process permits clients to tailor styles as they please.

Custom fashion jewelry business Radian is yet another example of how 3D printing can be applied for regional production. The Berlin-based company produces sensational rings, necklaces, and bracelets using 3D printing in primarily 2 ways: either by lost wax casting approaches or straight manufacturing via powder bed blend processes.

Prior to we proceed to the next area, the Bits & Parts project also is worthy of a short mention here. It permits anyone with an FDM printer to 3D print cool chairs almost completely. The Maker Puzzle Chair models can be downloaded for free and are made up of numerous little parts developed to fit most home printers.

Open Community

All the availability in both production and devices would just not be possible without the open-source design practices initiated by the RepRap community. The renewal of 3D printing was based on open-source concepts for both software and hardware.

The term "open source" is borrowed from software application advancement designs in cases when the code is open to anybody to see, utilize, and, most importantly, improve. This enables around the world cooperation amongst users with various backgrounds and talents.

3D printing today is still in terrific part open source. Companies like E3D, Prusa Research, and Lulzbot share their hardware illustrations and models with anyone, while open-source software application alternatives consist of Marlin firmware and the ever-popular OctoPrint.

This state of mind is also encompassed 3D models. Platforms like Thingiverse, Cults, and MyMiniFactory have countless free models to download that are shared among 3D printing users.

Last however definitely not least, an open-source neighborhood has promoted the creation of lots of unofficial support channels and academic online resources that have actually conserved a lot of us when we've faced problem with a print.

Brief Lead Times & Rapid Iteration

There's a reason 3D printing technologies were as soon as described as "rapid prototyping". The brief quantity of time required between creating and manufacturing a part makes this technology ideal for rapid design models.

This is particularly appropriate during item advancement, where the product needs several validations from idea to final functional testing. Because 3D printing does not need any unique tooling and setup for producing parts, all that's required is to customize the digital design and send it off to the 3D printer.

Fast version decreases the costs related to producing prototypes and shortens the advancement procedure, enabling the item to reach the marketplace quicker than ever. The capability to quickly repeat between different designs also produces a better product as the development group can verify and test proposed changes in a fast and low-cost way.

The vehicle industry has been leveraging this benefit of 3D printing for quite a long time now. For example, the engineering team at Ford depend on 3D printing for prototyping parts for the new Shelby GT500. Performance engineer Matt Titus claims this technology "improves the effectiveness of the designs, it dramatically reduced the time it required to develop the GT500-- and the costs associated with that."

Rapid iteration is not restricted to big corporates like Ford. The humble desktop 3D printer user likewise considerably take advantage of this benefit. Producing your own parts for whatever end can be a daunting job for some and the capability to quickly customize and re-print your designs is definitely the dish for success.

By now it must be more than clear how 3D printing has gained terrain throughout numerous industries worldwide. All the advantages currently mentioned in this article add to this broad variety of applications that's only expanding.

The availability and flexibility provided by 3D printing processes were often pointed out throughout this article, being maybe the traits that mostly stand out from the other production processes the industry is used to. Primarily because of such qualities 3D printing technologies are so diversely applied in sectors varying from health to airplane production.

The reality that there are several 3D printing strategies also contributes to this wide variety of applications. With SLA for precious jewelry and oral, SLS and SLM for engineering, and the great old FDM understood and enjoyed by a lot of hobbyists today. The possibilities are unlimited and the future looks brighter than ever for 3D printing.